While the term “fiber optic termination” might seem a little scary, it actually makes perfect sense when you dig into it. Fiber optic termination refers to various ways a length of fiber optic cable physically terminates.

It might help to think of it as reaching “the end of the line.” At this point, it terminates into a fiber optic connector. The reason for the termination is to either connect to a device or transceiver, splice two cables together, or create a multi-prong set-up with more branches.

Fiber termination is a vital concept when building a fiber optic network, and what you do when you come to the end of a cable is a pretty big deal. There are a few simple methods for stringing cables together. The first is by using connectors, which is the one we’ll focus on here, and the second is splicing. We’ll touch on it, but it’s not the main course.

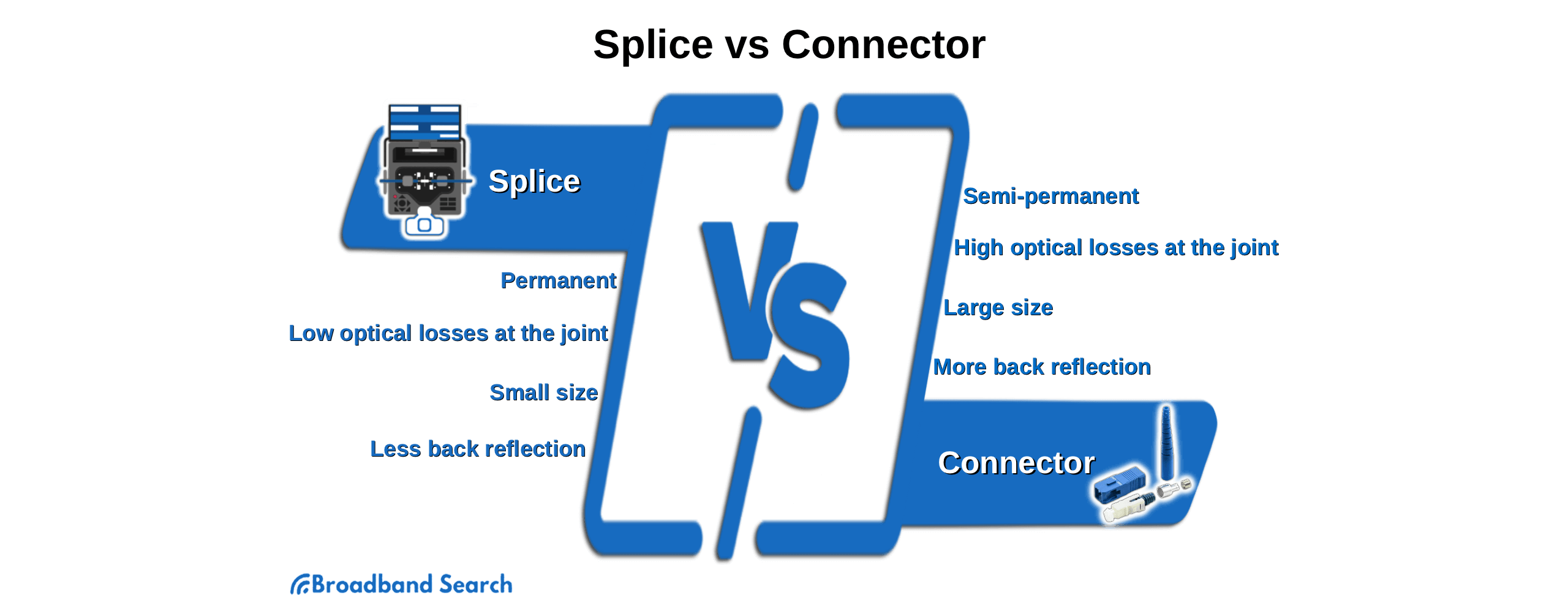

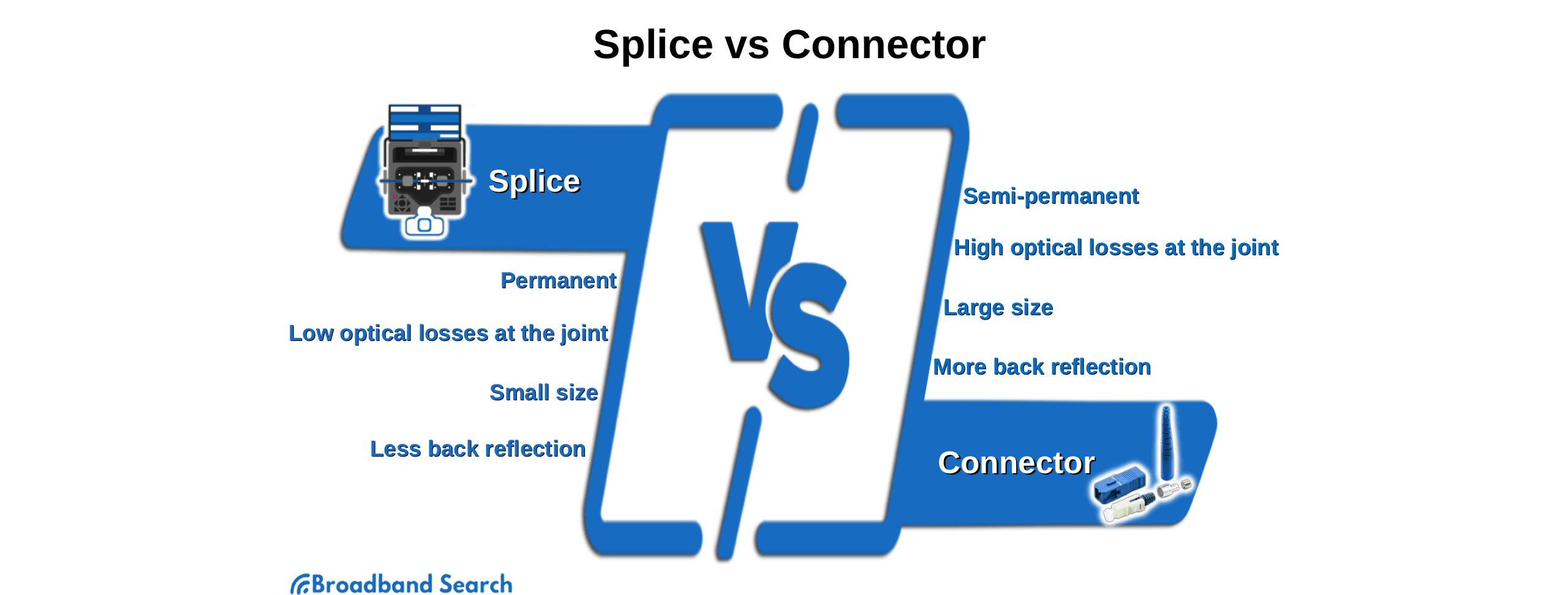

Check out the graphic below for a quick splicing summary.

A Short Primer on Splicing

Before we dive headlong into connectors, let’s take a quick look at fiber splicing, so you will at least understand what it involves.

Splicing is exactly like it sounds. It’s when you have the ends of two cables and need to connect them by splicing them together. A fiber splice is a bit of a beast than what you might typically think of as splicing because fiber optic cables consist of glass or plastic filaments in the middle.

These aren’t the easiest materials to join together.

This means the splicing process with fiber is more of a break than a cut. No matter. The ultimate goal is still the same - bringing the ends of the two cables together so that the signal continues uninterrupted and undiminished through the spliced area.

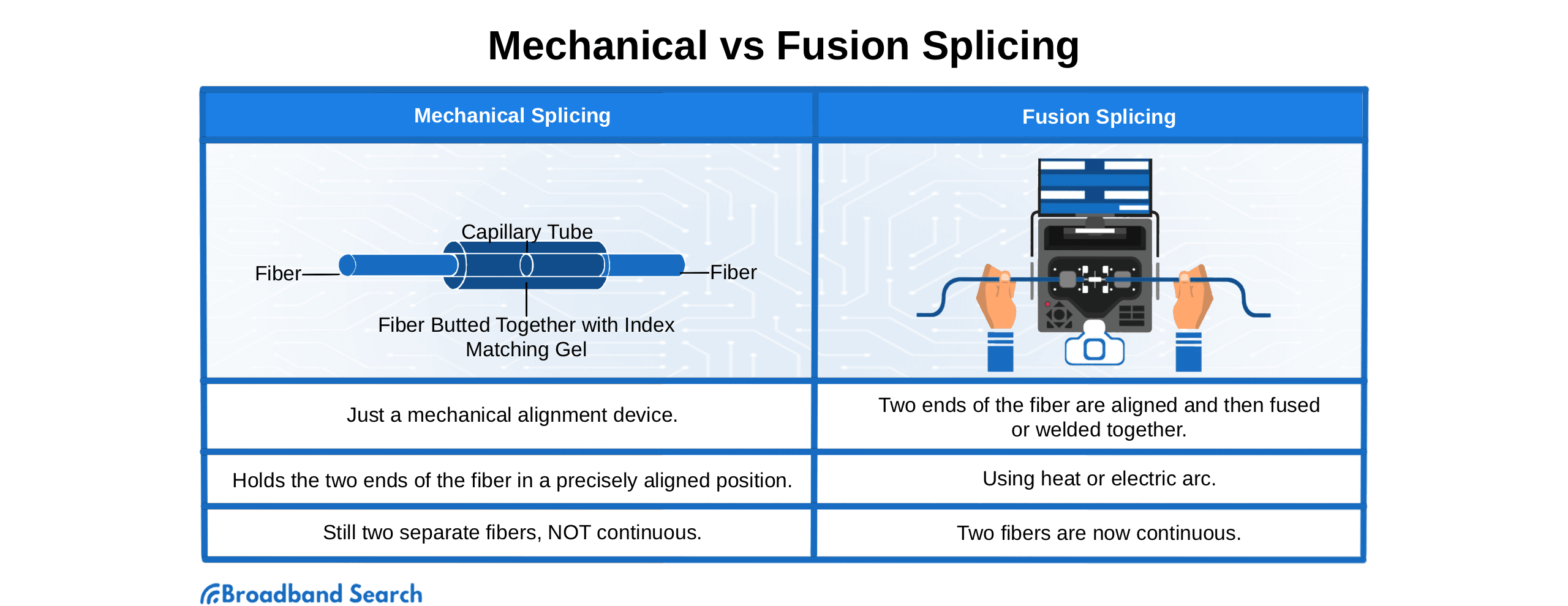

There are two ways of creating a fiber splice, mechanical and fusion. Splicing is a technique that is typically applied in the field and not so much at cable assembly houses, though this is not an exclusive fact.

Mechanical Splicing

Mechanical splicing, like its name blatantly hints, is a mechanical process that achieves a splice by precisely aligning the cable ends and securing them. Unlike fusion splicing, mechanical splicing doesn’t create a single continuous fiber. Still, the splice has to be precise enough that the signal still passes between the cable ends uninterrupted.

Most people in the industry would consider mechanical splicing an alternative technique to be used in the field when you’re short on equipment since it doesn’t require a fusion splicer.

Fusion Splicing

At this point, you’ve probably guessed that a fusion splice involves fusing the two fiber cable ends to become one continuous cable. Fusion splicing requires the tool we mentioned above, a fusion splicer. This allows the technician to create a precise alignment, hold them together, and then fuse or weld them using heat or an electric arc. The result is a continuous fiber cable.

What some consider to be the primary benefit of fusion splicing is that the splice lasts longer than mechanical splicing, though it is more expensive. A significant advantage is that the fiber cores are fused together, which results in less attenuation, which is a fancy way of saying that the signal degrades less.

The World of Fiber Optic Connectors

If splicing seems like too much of a hassle, you can always turn to fiber optic connectors. These small, flexible doodads are a quick way to connect fiber cable ends. They work well in termination situations where you need to connect a cable to a device, other fiber equipment, or want to join two cable ends without going to the trouble of splicing.

Lucent (LC) Connectors

A Lucent Connector (LC) is a popular ceramic connector that is best suited when there isn’t room for a regular fiber optic connection. It’s faster and easier to install than the others we will talk about shortly.

LC-compatible transceivers and networking components are gaining popularity in the Fiber In The Home (FITH) environment because it is often associated with limited space to run cables and the other components needed to set up a fiber network in your home or business.

An LC connector can be identified by a push-pull design that uses a latch instead of a locking tab. This connector is made of plastic and serves as a Small Form Factor (SFF) connector. These connectors are color-coded according to mode. Beige is multi-mode, and blue is single-mode.

The latter is where it performs the best.

Standard Connectors

Standard connectors, also known as SC connectors, are probably the most common in fiber optic environments today. Its simple, inexpensive-to-produce design is intended to make it a workhorse for techs who build, repair, and maintain fiber networks.

An SC connector’s push-pull design is similar to an LC connector but relies on a locking tab to secure the connection rather than the latch favored by the LC. SC connectors are especially popular in industries that use a lot of fiber cables, like telecom and datacom.

Ferrule Core (FC) Connectors

FC connectors were the first to be designed with a ceramic ferrule and a stainless steel screw mechanism to attach it in place. These materials are a drastic departure from most fiber optic connectors which rely on plastic throughout.

These days, FC connectors are an older product that is in the process of falling out of industry standards. You see them often in single-mode setups, but that is about it. You’ll rarely come across them in use in multi-mode.

One of the reasons FC connectors have fallen into disfavor is the screw mechanism we mentioned. It’s more challenging to use and takes longer to attach and unattach than the others. A more complex design incorporating metal makes them more expensive to produce, which is rarely good.

Still, FC connectors won’t be going away completely any time soon. They are still a popular option with moving machinery since the screw mechanism is more secure in an environment that demands that.

ST Connectors

ST connectors have the (mis)fortune of having been designed similarly to FC connectors which, unless your memory is shorter than a fruit fly, you’ll remember is losing popularity fast except in specific situations.

The one saving grace for ST connectors, which has kept them from falling out of favor quite as quickly as their FC brethren, is that its locking mechanism is similar to that of coaxial cables, which is to say, easier to use than an FC connector. Still, ST connectors are losing favor in place of LC and SC.

Multi-Position Optical Connectors (MPO)

MPO connectors are almost the same as MTO connectors, with the main difference being that the latter has an augmented design that makes it perfect for high-performance applications. MPO connectors are typically used in mechanical situations.

These connectors are basically mirror images. The connectors have 2 or 6 rows that incorporate either 12 or 16 separate fiber cables. Connections are made by pushing together the pin/hole design to mate a cable with another cable or electronic device.

MPO connectors are commonly found in high-speed, multi-mode links or pre-terminated cable groupings.

MT-RJ Connectors

You're mostly out of luck if you’re looking to incorporate MT-RJ connectors into a current project. They are no longer used for new installations, though they can still be scavenged in small numbers for repair jobs. Further, the only types of systems that MT-RJ works with are multi-mode cables with duplex fibers.

The design is similar to MPO with a pin/hole arrangement that mates the ferrules, though you may run across a few plug/jack-designed MT-RJ connectors. The bottom line is that these connectors will be gone for good off the face of fiber network building someday.

Fiber Optic Connectors vs. Splicing

As a review, remember that the main difference between fiber optic connectors and splicing is that connectors do not need a splicer machine, which can cost upwards of $40,000. This cost is an obvious reason that technicians and companies opt for alternative solutions whenever they can.

Why We Like Fiber Optic Connectors

While no one would legitimately claim that you should always use a fiber optic connector instead of a splice, the cost of splicing makes it worth taking the time to see if you need to make a splice or could choose something else - like a connector.

Some of the obvious advantages of fiber optic connectors:

- Easily change network connections without it being a big deal

- Access the network for testing under a variety of configurations

- Easier to implement

- Saves time and money with no need for a splicer machine

Considering the preceding points, technicians should use fiber optic connectors rather than create a splice unless some overriding factor contraindicates.

Why We Like Splicing

The glaringly obvious reason you would choose to make a splice rather than use a fiber optic connector comes down to quality and strength. Unless the technician is bad at using a splicer, any splice should be stronger and more reliable than any connector.

You also tend to end up with lower insertion loss with a splice. For those unfamiliar with this term, it refers to optical power (internet signal) that is not transferred through the splice and ends up being radiated out of the fiber instead, where it doesn’t do anyone any good.

Final Thoughts

Let’s rewind to our title: Why Fiber Optic Connectors Are (Sometimes) Better Than Splicing. Some network situations are inappropriate for the use of fiber connectors. In such environments, opt for a splice.

The bottom line is that fiber optic splicers or technicians should consider whether a project can be successfully completed using fiber connectors. Some can. For those, it makes no sense to incur the expense and time required to drag out the splicing machine.

If there is anything about the splices in the project that seem to call for something stronger and more reliable and the company can stand the expense, by all means, go for the splice.

Nowadays, the ultimate consideration often comes down to how you arrive at the fastest, most reliable internet connection. For this part of the equation, you can test your fiber internet speed with our free online tool. This will let you know whether your fiber connector build or repair is adequate or you’re losing too much signal at the connection and need something better - maybe a splice?

FAQ

What is multi-mode fiber?

A multi-mode fiber is usually used for data travel over short distances, such as within a building or campus. These cables have a large core diameter and can handle speeds up to 100 Gbps. Multiple light modes can be propagated, but modal dispersion limits how far it can reliably carry a signal.

What is the difference between simplex and duplex cables?

A simplex fiber cable consists of a single glass or plastic filament inside a protective outer jacket. It’s cheaper but offers higher speed and is best used in applications that focus only on transmitting data in one direction with no need to receive any back. A duplex cable is two glass or plastic filaments wrapped inside a protective jacket. It’s basically two simplex cables put together. The cost of duplex is higher, but it has the advantage of being able to send and receive data.

Should I clean fiber optic connectors?

Fiber optic connectors should be cleaned periodically. Oil and dust can build up over time and result in signal degradation. Such contaminated particles can be invisible to the naked eye but block an entire cable fiber filament. The preferred cleaning method is called combination cleaning, which advises using a wet-to-dry cycle that includes a very small amount of solvent.

What is single-mode fiber?

Single-mode fiber cables are used to transmit data over longer distances than multi-mode. As the name suggests, single-mode fiber consists of a single glass fiber strand. This type of fiber is limited to a single transmission mode but carries higher bandwidth. What it gives up in volume, it makes up in distance.

How far can a fiber signal be transmitted?

The accepted distance that a fiber signal can travel is 60 miles before it starts to degrade. Fiber internet providers install transmit huts every 40 to 60 miles that collect the signal and re-transmit it down the line to the next segment at full strength.